Recent Posts

Carrlane Handles: Shapes and Fastening Types Explained

Posted on

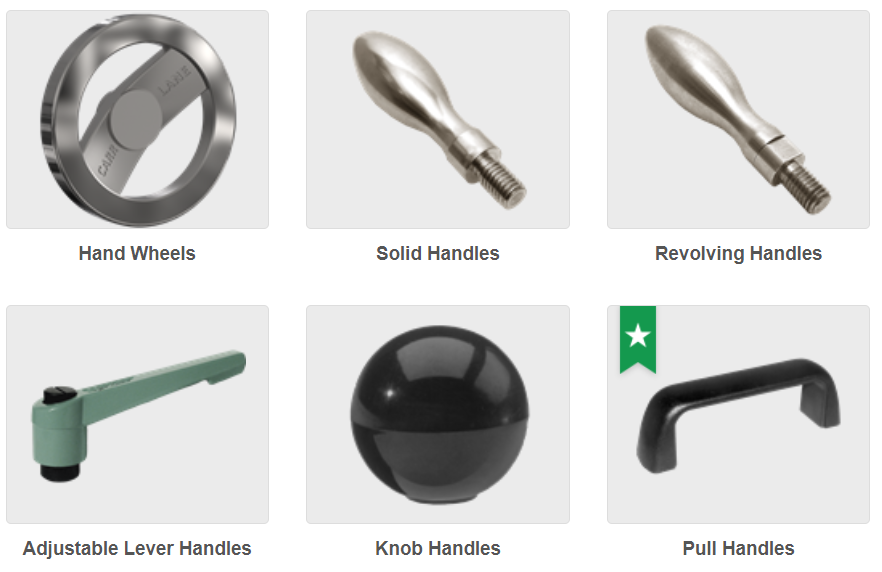

Carrlane offers a wide range of handles tailored to meet various needs in the engineering and mechanical industry. Their handles not only promise durability but also ease of use, catering to specific tasks and machinery. We will delve into the different shapes and fastening types of Carrlane handles.

Shapes of Carrlane Handles

1. Straight Handle

- Description: These handles are linear without any bends. They provide a straightforward grip and are often found on tools and machines that require direct force.

2. Crank Handle

- Description: Featuring a bent structure, crank handles are designed for applications where turning is needed, such as on milling machines or lathes.

3. T-handle

- Description: Shaped like the letter 'T', these handles offer an ergonomic grip and are commonly used where torque is required, like in tightening or loosening.

4. Fold-Down Handle

- Description: Ideal for situations where space is a constraint, these handles can be folded down after use, ensuring they don't protrude and cause obstructions.

5. Lever Handle

- Description: Lever handles are typically longer and curved, allowing for a larger range of motion. They are suitable for operations that need leverage.

6. Revolving Handle

- Description: These handles rotate around a fixed point, making them perfect for machinery where continuous turning actions are necessary.

Fastening Types of Carrlane Handles

1. Threaded Stud

- Characteristics: This type has a protruding threaded portion allowing it to be screwed into a threaded hole. The threading ensures a firm attachment.

2. Through-Hole

- Characteristics: A handle with a through-hole can be fastened using a bolt that passes through the hole, ensuring a secure fit.

3. Push Button

- Characteristics: These are typically found in fold-down handles. A button, when pressed, releases the handle allowing it to be folded.

4. Set Screw

- Characteristics: Set screw fastening involves a screw that helps to secure the handle to a shaft or another component. The screw can be tightened or loosened as required.

5. Keyway

- Characteristics: A keyway fastening has a slot designed to fit a specific key shape. When the key is inserted into the keyway, it ensures that the handle doesn't rotate undesirably.

Conclusion

Carrlane's extensive range of handles, both in terms of shape and fastening types, ensures that there's a handle for every need, whether it's for machinery, tools, or any other equipment. Their commitment to quality and versatility makes their handles stand out and find applications in various industrial scenarios. When choosing a Carrlane handle, understanding the shape and fastening type required for your specific task can lead to safer, more efficient operations.

Loading... Please wait...

Loading... Please wait...