Recent Posts

Demystifying Fixture Components: A Comprehensive Guide to Choosing the Right Supplier

Posted on

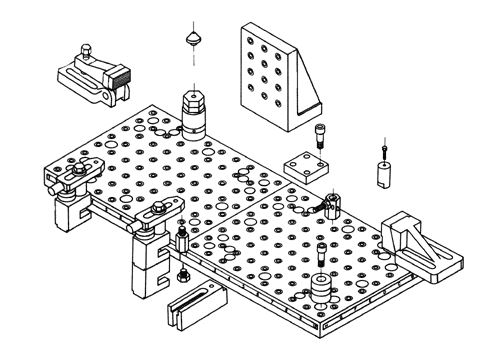

As a professional in the fixture manufacturing industry, you understand the importance of selecting the right components for your fixtures. However, finding a reliable supplier that offers top-quality components can be a challenging task. In this article, we will delve into the various components used in fixtures, discuss key considerations for choosing a supplier, and provide valuable insights to help you make informed decisions. Read on to optimize your fixture manufacturing process and streamline your procurement efforts.

- Essential Components for Superior Fixtures:

a) Clamps and Workholding Devices: These components are crucial for securely holding workpieces during machining operations. Look for clamps that offer excellent gripping force, durability, and adaptability to different workpiece sizes and shapes.

) Locators and Positioning Elements: Locators ensure accurate and repeatable positioning of workpieces within the fixture. Evaluate locators based on their precision, material quality, and ease of adjustment to ensure consistent alignment.

c) Tooling and Inserts: Tooling elements such as cutting tools, drills, and inserts play a vital role in achieving precise and efficient machining. Consider the compatibility of the tooling with your machining processes, the range of available sizes, and the longevity of the inserts.

d) Actuators and Hydraulic Components: These components facilitate the movement and clamping mechanisms of fixtures. Seek reliable actuators and hydraulic systems that offer smooth operation, high load capacity, and precise control for optimal performance.

2. Key Factors in Choosing a Supplier:

a) Quality and Reliability: Look for suppliers with a track record of delivering high-quality components that meet industry standards. Ensure they have stringent quality control processes in place to guarantee consistency and reliability.

b) Customization Capabilities: Opt for a supplier that can customize components to match your specific requirements. This includes offering various sizes, materials, and configurations to ensure compatibility with your fixture designs.

c) Competitive Pricing: Evaluate suppliers based on their pricing structure and overall value for money. While cost is a factor, consider the quality and longevity of the components to avoid compromising on reliability.

d) Timely Delivery: On-time delivery is crucial to keep your manufacturing processes running smoothly. Choose a supplier known for their promptness and ability to meet your deadlines consistently.

e) Customer Support: Excellent customer service and technical support are invaluable. Seek suppliers who provide prompt assistance, offer technical expertise, and are responsive to your queries and concerns.

3. Building Relationships with Trusted Brands:

a) Research and Reviews: Conduct thorough research on potential suppliers. Check online reviews, testimonials, and industry forums to gather insights on the reputation and customer satisfaction of different brands.

b) Certifications and Compliance: Ensure that the supplier adheres to industry standards and possesses relevant certifications. This demonstrates their commitment to quality and compliance with regulatory requirements.

c) Longevity and Stability: Consider the supplier's history and stability in the market. A well-established brand with a strong presence is more likely to offer reliable components and consistent support.

d) Collaborative Partnerships: Look for suppliers who prioritize building long-term relationships and offer ongoing support. A collaborative partnership can result in enhanced customization options, reliable supply chains, and potential cost savings.Choosing the right components and suppliers for your fixture manufacturing needs is critical to delivering high-quality products and optimizing your manufacturing processes.

By understanding the essential components, key factors in selecting a supplier, and building relationships with trusted brands, you can streamline your procurement efforts and ensure a smooth and efficient production workflow. Invest time in research, assess supplier capabilities, and prioritize quality, reliability, and customer support to make informed decisions that drive your business forward.

Loading... Please wait...

Loading... Please wait...