Recent Posts

Factors to consider while designing your fixtures

Posted by on

A fixture is a tool commonly used in the manufacturing industry to hold a device and to be able to machine or assemble a large number of parts, always guaranteeing the interchangeability of the components.

One of the purposes of the fixtures is to reduce costs, so they must be designed in such a way that the cost reduction is greater than the cost of implementing the device.

Here are some of the factors that should be taken into account when designing a fixture:

The component: This design should be studied carefully, making sure that the work is done in an appropriate sequence.

The machine capacity: The capacity and type of the machine should be considered.

Production requirements: The design must be made based on actual production needs. Afterwards comes the decision to use manual or automatic tools.

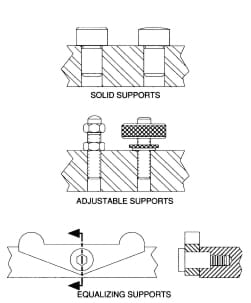

Location: The location must ensure an equal distribution of forces throughout the operation sequence.

The movement of the work piece should be restricted.

It must be infallible to avoid incorrect locations on the work piece.

It should facilitate an easy and fast loading of the work piece.

Sharp corners should be avoided.

At least one reference surface must be established.

Load and unload adjustments: There must be adequate clearance for loading and unloading. So that the process becomes fast and easy. The variation in size must be accepted. It must be hard and not sticky material.

Clamping adjustments: We should preferably use quick acting clamps. The clamping method used must not damage our work piece.

Rigidity and vibration: Must possess sufficient rigidity and robustness. It should not vibrate, as it can lead to unwanted movements of the work piece and tools.

Security: You must ensure total security in the operation.

Loading... Please wait...

Loading... Please wait...