Blog

Recent Posts

Toggle Clamps: Holding capacity & clamping force

Posted by on

Toggle Clamps: Holding capacity & clamping force

Toggle clamps have specifications in terms of holding capacity and clamping force. It’s important to distinguish the difference between these two concepts and to know how they are measured in order to make the best decision when choosing clamps for each application.

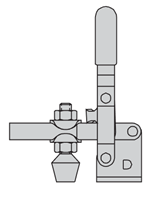

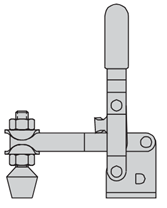

Spindle position for maximum capacity Spindle position for maximum reach

Holding Capacity:

The holding capacity specified for each toggle clamp refers to the maximum force that the spindle on the clamp can exert without deforming permanently. It is important to take into account that the maximum force applied to the toggle clamps is when the spindle is positioned in the closest point to the handle, and it’s said capacity will be lower at the farthest end of the handle.

Clamping Force:

The clamping force is usually less than the defined holding capacity. Here we refer to the force applied to the par to be fastened when closing and securing with the toggle clamp. This allows the clamps to have sufficient capacity to withstand the external forces that occur in the cutting process of the part. The actual clamping force depends on several factors:

- Position of the spindle

- Appropriate adjustment of the height of the spindle.

- The type of spindle cushioning (uncushioned hex-head spindles provide the greatest force).

- Workpiece material

- The clamp's mechanical advantage

In most cases about half the clamping capacity can be applied manually with a medium effort.

CL5: 5-Axis workholding system

The CL5, workholding with 5 axis quick change is comprised of 3 methods: fixture plate mounted on a rotary table, a Quintus quick-change riser mounted on a rotary table or subplate mounted on a rotary table.Designed to remove the piece from the machine table, the Quintus quick-change lifter allows access to 5-sided parts.The CL5 offers 3 clamping methods:1. Fixing [...]

Loading... Please wait...

Loading... Please wait...